Conquering Low Water Pressure: Your Guide to Water Pump Pressure Switch Success

Is your shower more of a dribble than a refreshing cascade? Is your washing machine struggling to fill? Low water pressure can be a major inconvenience, and often, the culprit is a faulty water pump pressure switch. This comprehensive guide will walk you through everything you need to know about this small but mighty component, empowering you to diagnose, troubleshoot, and even replace your water pump pressure switch like a pro.

Imagine a world without the convenience of consistent water pressure. No invigorating showers, no effortlessly clean dishes, no lush green lawns. The water pump pressure switch plays a crucial role in maintaining the water pressure we rely on every day. It acts as the brain of your water pump system, telling the pump when to turn on and off based on the pressure in your pipes. When this switch malfunctions, it disrupts the entire system, leading to frustratingly low water pressure or even complete pump failure.

The history of water pump pressure switches is intertwined with the development of modern plumbing and pressurized water systems. Early systems relied on manual pumps and gravity, but as demand for consistent water pressure grew, so did the need for automated solutions. The pressure switch emerged as a key component, allowing pumps to operate automatically and maintain a desired pressure range. This advancement significantly improved the efficiency and convenience of water systems in homes, businesses, and agriculture.

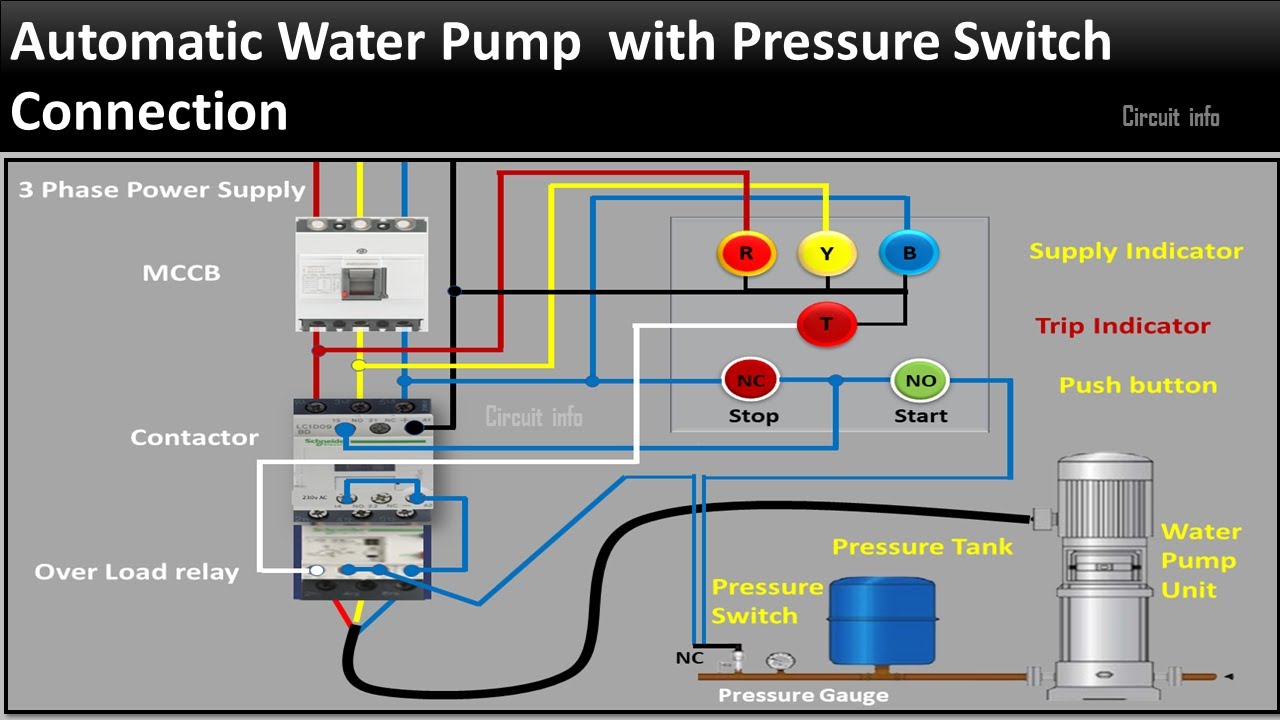

Understanding the function of a water pump pressure switch is essential for effective troubleshooting and replacement. The switch contains a diaphragm that reacts to changes in water pressure. When the pressure drops below a preset level, the diaphragm activates the switch, turning the pump on. Conversely, when the pressure reaches the upper limit, the diaphragm deactivates the switch, turning the pump off. This cycle ensures a consistent supply of water at the desired pressure.

Several issues can arise with a water pump pressure switch, leading to low water pressure, erratic pump cycling, or even complete pump failure. A common problem is a faulty diaphragm, which can become worn or damaged over time, preventing it from accurately sensing pressure changes. Mineral buildup or debris can also interfere with the switch's operation. In some cases, the electrical contacts within the switch can corrode or fail, preventing the pump from turning on or off properly. Recognizing these potential issues is the first step towards resolving your water pressure woes.

Replacing a faulty water pump pressure switch offers several benefits. Firstly, it restores consistent water pressure, eliminating the frustration of weak showers and struggling appliances. Secondly, it can improve the efficiency of your water pump system, preventing it from running unnecessarily and potentially extending its lifespan. Lastly, replacing a faulty switch can prevent more serious problems, such as pump burnout or damage to your plumbing system.

Before replacing your water pump pressure switch, turn off the power to the pump and drain the pressure from the system. Carefully remove the wires connected to the old switch, noting their positions. Install the new switch, ensuring the wires are connected correctly. Restore power and water to the system, and check for leaks and proper operation.

Advantages and Disadvantages of DIY Replacement

| Advantages | Disadvantages |

|---|---|

| Cost Savings | Potential for Errors |

| Sense of Accomplishment | Risk of Damage |

Best practices for water pump pressure switch replacement include: using the correct replacement switch for your pump model, properly grounding the switch, using Teflon tape on pipe threads to prevent leaks, double-checking all connections, and testing the system thoroughly after installation.

Frequent Questions:

1. How do I know if my pressure switch is bad? (Inconsistent pressure, short cycling)

2. Can I adjust the pressure setting? (Yes, with the adjustment screws)

3. How long do pressure switches last? (Several years with proper maintenance)

4. What causes a pressure switch to fail? (Wear and tear, mineral buildup, electrical issues)

5. Can I replace the switch myself? (Yes, with basic plumbing skills)

6. What tools do I need? (Wrenches, screwdriver, Teflon tape)

7. Where can I buy a replacement switch? (Hardware stores, online retailers)

8. What is the cost of a new switch? (Varies depending on the model)Tips and tricks: Take photos before disconnecting wires, use a pressure gauge to verify pressure settings, and consult your pump's manual for specific instructions.

In conclusion, the water pump pressure switch is a vital component of any pressurized water system. Understanding its function, recognizing signs of failure, and knowing how to replace it can empower you to maintain consistent water pressure and avoid costly repairs. By following the guidelines and best practices outlined in this article, you can confidently tackle water pump pressure switch replacement and enjoy the convenience of a reliably pressurized water system. Don’t let low water pressure dampen your day – take control and restore the flow! This small investment in time and effort can save you money, prevent future headaches, and ensure a steady stream of water for all your needs.

Boat battery disconnect secrets your 12v lifeline

Elevate your space with the mystique of sherwin williams slate tile hues

Cimb bank shah alam seksyen 14 navigating your financial needs