Grade 8.8 Bolt Torque Specifications

Securing a structure, whether it's a towering skyscraper or a simple household appliance, relies on the integrity of its fasteners. Among these crucial components, bolts play a vital role, and understanding their properties is paramount. This exploration delves into the world of grade 8.8 bolts, focusing on the importance of accurate torque specifications.

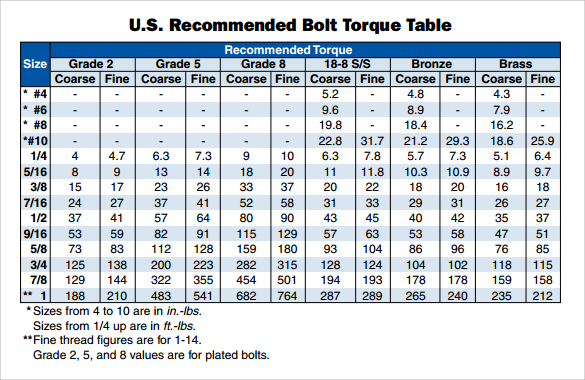

Imagine the consequences of a loosely fastened bolt in a critical application. The potential for failure is significant, potentially leading to damage, malfunction, or even injury. That's why having access to reliable torque guidelines, often presented in a grade 8.8 bolt torque chart PDF, is so crucial for engineers, technicians, and anyone working with these fasteners.

While a free PDF version of a grade 8.8 bolt torque chart can be a valuable resource, it's essential to understand its context within the broader landscape of bolt specifications. A grade 8.8 designation signifies specific mechanical properties, including tensile strength and yield strength. Torque specifications are directly related to these properties, ensuring the bolt is tightened enough to secure the joint without exceeding its limits.

Finding a free grade 8.8 bolt torque chart PDF online requires careful consideration of the source. Accuracy is paramount, and referencing reputable organizations or engineering handbooks is recommended. PDO (Petroleum Development Oman), for example, might have specific guidelines for bolt usage in their operations, reflecting industry best practices.

Beyond simply finding a chart, comprehending the factors influencing torque values is crucial. Lubrication, thread condition, and the material being fastened all play a role. Additionally, the concept of preload, the tension created in the bolt by tightening, is fundamental to achieving a secure and reliable joint.

Historically, bolt tightening relied heavily on experience and feel. However, with advancements in engineering and the increasing complexity of structures, the need for precise torque control became evident. Torque charts and wrenches provide the tools for consistent and reliable fastening, minimizing the risk of failure.

One significant issue related to bolt torque is over-tightening. This can lead to stripped threads, bolt failure, or damage to the materials being joined. Conversely, under-tightening can result in joint loosening and potential structural instability.

Several benefits arise from utilizing accurate grade 8.8 bolt torque specifications. Firstly, it ensures the integrity and safety of the assembled structure. Secondly, it reduces the risk of costly repairs or replacements due to fastener failure. Thirdly, consistent torque application contributes to the longevity and reliability of the bolted connection.

When seeking a grade 8.8 bolt torque chart, prioritize reputable sources like engineering handbooks or standards organizations. Verify the chart's applicability to your specific application, considering factors like lubrication and material. Using calibrated torque wrenches is essential for accurate and consistent tightening.

Advantages and Disadvantages of Using Torque Charts

| Advantages | Disadvantages |

|---|---|

| Ensures proper bolt tightening | Requires accurate charts and tools |

| Increases safety and reliability | Can be time-consuming for large assemblies |

Best practices include cleaning threads before assembly, using appropriate lubricants, and following a consistent tightening sequence. Regularly calibrating torque wrenches ensures accuracy, and documenting the tightening process provides valuable records.

Challenges in implementing torque specifications often involve variations in bolt quality, environmental factors, and human error. Solutions include using high-quality bolts, controlling environmental conditions, and providing adequate training for personnel.

FAQs often center on the units of torque (Nm or lb-ft), the difference between dry and lubricated torque, and the importance of preload. Understanding these concepts is crucial for proper bolt usage.

A tip for ensuring accurate torque is to use a torque wrench with a clear audible click or digital readout. This provides immediate feedback on the applied torque, reducing the risk of over- or under-tightening.

In conclusion, understanding and applying correct torque specifications for grade 8.8 bolts is fundamental to ensuring the safety and reliability of any assembled structure. Accessing reputable torque charts, using calibrated tools, and adhering to best practices contribute to achieving optimal fastening results. While finding a free grade 8.8 bolt torque chart pdf might be convenient, prioritizing accuracy and referencing trusted sources are paramount. Investing the time and effort in proper bolt tightening techniques pays dividends in the long run, preventing costly failures and ensuring long-lasting structural integrity. Take the time to research, learn, and apply these principles for a more secure and reliable outcome in all your fastening endeavors.

Unlocking family connection the ultimate guide to creative family group chat names

Sw 7075 web gray exterior the mysterious hue taking over

Medieval knights seriously how did they do it