Mastering Hydraulic System Design with Symbols

Imagine trying to assemble a complex piece of machinery without a clear set of instructions. Frustrating, right? That's precisely why hydraulic symbols exist. They are the language of hydraulic system design, providing a standardized visual representation of components and their functions, allowing engineers and technicians to communicate effectively and ensure efficient system operation.

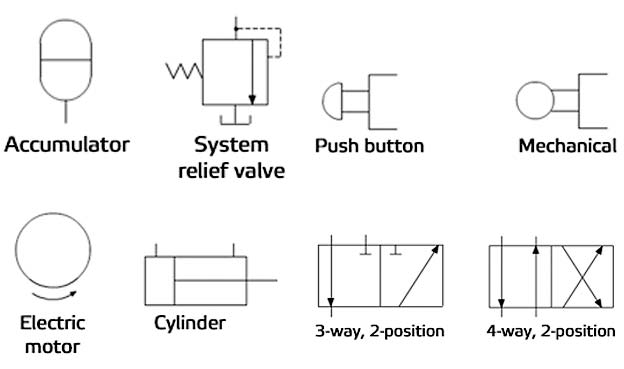

Hydraulic symbols represent various components, from pumps and valves to actuators and filters, allowing for a concise and universally understood schematic. They simplify complex designs and facilitate collaboration amongst engineers involved in the design, implementation, and maintenance of hydraulic systems. Understanding these symbols is crucial for anyone working with hydraulics.

Hydraulic systems are the powerhouses behind countless applications, from construction equipment and agricultural machinery to aircraft and industrial automation. These systems rely on the controlled flow of pressurized fluid to generate, transmit, and control power. Without a clear way to represent these systems, design, troubleshooting, and maintenance would be significantly more challenging.

The earliest forms of hydraulic symbols emerged from the need for a standardized representation of system components. As hydraulic systems grew more complex, so did the need for a universal language to depict them. Over time, organizations like the International Organization for Standardization (ISO) developed standardized symbols to ensure clarity and consistency across different industries and countries.

One of the main issues related to hydraulic symbols is the potential for misinterpretation if not used correctly. While standardized symbols exist, variations or inconsistencies can lead to confusion and errors in system design or maintenance. Therefore, proper training and adherence to standardized symbol usage are essential for effective communication and preventing costly mistakes.

A hydraulic pump symbol, for example, depicts the component responsible for pressurizing the hydraulic fluid. A control valve symbol indicates a device that regulates fluid flow and direction. Even seemingly minor components like filters and reservoirs have designated symbols, ensuring a complete and accurate representation of the entire system.

One significant benefit of using hydraulic symbols is improved communication. They provide a clear and concise way for engineers, technicians, and operators to understand the system's layout and functionality. This minimizes the risk of misinterpretations and errors during design, maintenance, and troubleshooting.

Another key advantage is enhanced efficiency in system design and analysis. Hydraulic symbols allow for a quicker understanding of the system's operation, making it easier to identify potential issues and optimize performance. This is particularly important in complex systems where numerous components interact.

Furthermore, the use of hydraulic symbols simplifies troubleshooting and maintenance. Technicians can quickly locate and identify faulty components based on the schematic, reducing downtime and repair costs. This clear visual representation speeds up the diagnostic process and ensures efficient repairs.

Advantages and Disadvantages of Using Hydraulic Symbols

| Advantages | Disadvantages |

|---|---|

| Clear and concise communication | Requires training and understanding of standards |

| Enhanced efficiency in system design and analysis | Potential for misinterpretation if not used correctly |

| Simplified troubleshooting and maintenance | Variations or inconsistencies can lead to confusion |

Best Practices for Implementing Hydraulic Symbols:

1. Adhere to ISO standards: Using standardized symbols ensures consistency and clarity.

2. Use clear and legible diagrams: Ensure symbols are easy to read and understand.

3. Provide a legend: Include a key explaining all symbols used in the diagram.

4. Use consistent scaling: Maintain a uniform scale for all symbols in the schematic.

5. Keep diagrams up-to-date: Update diagrams to reflect any changes made to the system.

Frequently Asked Questions:

1. What are hydraulic symbols? - They are graphical representations of components in a hydraulic system.

2. Why are hydraulic symbols important? - They facilitate clear communication and efficient system design.

3. Where can I find a comprehensive guide to hydraulic symbols? - ISO standards provide detailed information.

4. How do I interpret hydraulic symbols? - Refer to a symbol legend or ISO standards for clarification.

5. What are some common hydraulic symbols? - Examples include pumps, valves, actuators, and filters.

6. Are hydraulic symbols universally standardized? - Efforts are made for standardization, but some variations may exist.

7. How can I learn more about hydraulic symbols? - Numerous resources, including books and online tutorials, are available.

8. What is the importance of using standardized hydraulic symbols? - Standardized symbols ensure clarity and prevent misinterpretations.

Tips and Tricks:

Use software tools for creating and managing hydraulic diagrams. These tools often have built-in libraries of standard symbols, making it easier to create accurate and consistent schematics.

In conclusion, hydraulic symbols are indispensable for anyone working with hydraulic systems. They provide a universal language for communicating complex designs, facilitating efficient troubleshooting, and ensuring smooth operation. By understanding the function and importance of these symbols, engineers and technicians can optimize system performance, minimize downtime, and enhance safety. Mastering this symbolic language is essential for anyone involved in the design, implementation, or maintenance of hydraulic systems. The ability to accurately interpret and utilize hydraulic symbols ensures clear communication, efficient troubleshooting, and ultimately, the successful operation of hydraulic systems across various industries. Investing time in understanding and applying these symbols is a crucial step towards maximizing the potential of hydraulic technology. Embrace the language of hydraulics, and you’ll unlock a world of efficient and powerful systems.

Unraveling insect breathing exploring the tracheal respiration diagram

Conquering madisons festival scene your ultimate guide

Show your spirit the ultimate guide to green bay packer dog collars