Mastering Toyota Axle Nut Torque: Your Guide to a Secure Ride

Ensuring the safety and reliability of your Toyota hinges on many factors, and one often overlooked yet crucial aspect is the correct tightening of your axle nuts. Proper Toyota axle nut torque is paramount for maintaining wheel stability, preventing premature wear and tear, and ensuring a smooth, safe driving experience. Neglecting this seemingly minor detail can lead to serious consequences, ranging from annoying vibrations to catastrophic wheel detachment. This comprehensive guide will delve into the world of Toyota axle nut torque, providing you with the knowledge and resources you need to keep your vehicle running smoothly and securely.

Imagine driving down the highway, feeling a subtle vibration that gradually intensifies, or worse, experiencing a complete wheel failure. These scenarios can often be traced back to improperly torqued axle nuts. Applying the correct Toyota axle nut torque specifications is not just a mechanical procedure; it's a fundamental step in ensuring your safety and the longevity of your vehicle. By understanding the importance of proper torque, you're taking proactive steps to prevent potential hazards and costly repairs.

Toyota axle nut torque specifications vary depending on the specific model and year of your vehicle. Consulting your owner's manual or a reliable online database is essential for determining the precise torque value for your Toyota. Using a calibrated torque wrench is crucial for achieving accurate tightening and avoiding over- or under-torquing, both of which can have detrimental effects. Over-torquing can damage the wheel studs, axle, or even the hub, while under-torquing can lead to loosening and potential wheel detachment.

The history of axle nut torque specifications goes hand in hand with the evolution of automotive engineering. As vehicles became more complex and performance-oriented, the need for precise tightening specifications became increasingly critical. Toyota, known for its commitment to quality and reliability, has always emphasized the importance of adhering to these specifications. The development of torque wrenches and standardized torque values has significantly contributed to enhanced vehicle safety and performance.

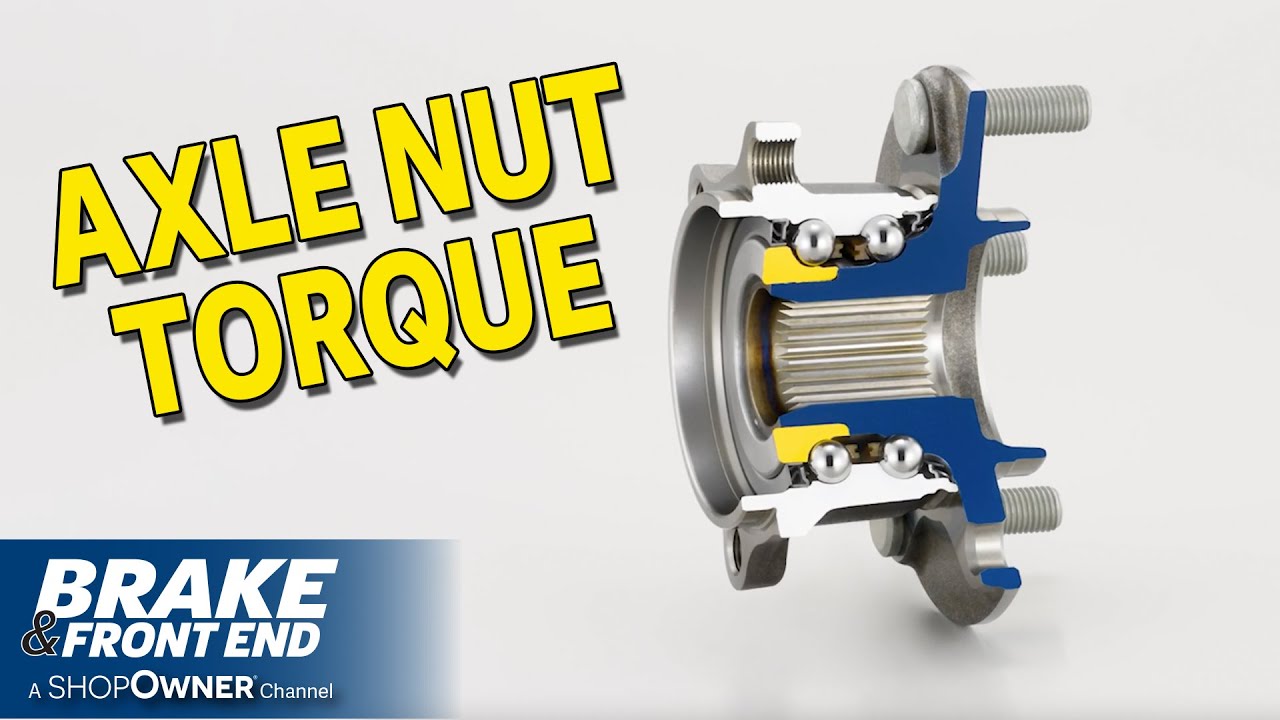

Proper Toyota front axle nut torque and Toyota rear axle nut torque are essential for maintaining the integrity of the wheel assembly. These nuts secure the wheel hub to the axle, ensuring that the wheels remain firmly attached and aligned. The precise torque specifications ensure that the clamping force is sufficient to prevent movement while avoiding excessive pressure that could damage the components. This careful balance is vital for optimal performance and safety.

One of the key benefits of proper Toyota axle nut torque is enhanced safety. Securely fastened wheels contribute to stable handling and predictable braking, reducing the risk of accidents. Another benefit is improved vehicle longevity. Correctly torqued axle nuts minimize wear and tear on the wheel bearings, hubs, and other related components, extending their lifespan. Finally, proper torque contributes to a smoother, more comfortable ride by reducing vibrations and noise.

To ensure proper Toyota axle nut tightening, follow these steps: 1) Consult your owner's manual for the correct torque specification. 2) Use a calibrated torque wrench. 3) Tighten the nuts in a star pattern to distribute the force evenly. 4) Recheck the torque after driving a short distance. These steps will help you achieve optimal tightening and ensure the safety and reliability of your vehicle.

Advantages and Disadvantages of Focusing on Toyota Axle Nut Torque

| Advantages | Disadvantages |

|---|---|

| Enhanced Safety | Requires Specific Tools (Torque Wrench) |

| Improved Vehicle Longevity | Can be Time-Consuming if Unfamiliar |

| Smoother Ride | Risk of Damage if Incorrect Torque Applied |

Best practice is to always consult your vehicle's owner's manual for the most accurate and up-to-date torque specifications. Using a high-quality, calibrated torque wrench is essential for achieving precise tightening. Following a star pattern when tightening the axle nuts ensures even distribution of force. Regularly inspecting the axle nuts for signs of loosening is also recommended.

A common challenge is the difficulty in accessing the axle nuts, particularly on vehicles with complex suspension systems. The solution is to use appropriate tools and techniques, such as extensions and swivel adapters, to reach the nuts effectively.

FAQ: What is the typical Toyota axle nut torque? The specific torque varies depending on the model and year. Consult your owner's manual. What happens if I overtighten the axle nut? Overtightening can damage the wheel studs, axle, or hub. What are the signs of a loose axle nut? Vibrations, unusual noises, or even wheel wobble can indicate a loose axle nut.

One tip is to clean the threads of the axle nuts and studs before tightening to ensure accurate torque readings. Another trick is to mark the position of the nuts after tightening so that you can easily visually inspect for any loosening.

In conclusion, understanding and applying the correct Toyota axle nut torque is a critical aspect of vehicle maintenance that directly impacts safety, performance, and longevity. While it may seem like a small detail, proper torque can prevent costly repairs and potentially dangerous situations. By following the guidelines outlined in this article, consulting your owner's manual, and utilizing the correct tools, you can ensure that your Toyota's wheels remain securely fastened, providing a smooth, safe, and reliable driving experience for years to come. Don't underestimate the importance of this seemingly minor detail. Take the time to learn the correct specifications and procedures for your specific Toyota model, and invest in a quality torque wrench. Your safety and the well-being of your vehicle depend on it.

Need for speed heat mods free pimp your ride without spending a dime

Decoding the 5x120 bolt pattern which cars roll with it

Unlock serenity with sherwin williams rainwater your guide to tranquil spaces