Mastering Your Jeep Wrangler's Lug Nut Torque: A Comprehensive Guide

Imagine this: you're cruising down a scenic backroad in your Jeep Wrangler, enjoying the open air and rugged terrain. Suddenly, you feel a wobble. A loose wheel? A chilling thought. Properly torqued lug nuts are the silent guardians against this nightmare scenario, ensuring your wheels stay securely attached. Understanding the importance of correct Jeep Wrangler lug nut torque is vital for every Wrangler owner, contributing to safety and preventing costly repairs.

The seemingly simple act of tightening lug nuts is more nuanced than you might think, especially for a vehicle designed for off-road adventures like the Wrangler. Applying the correct torque—the rotational force used to tighten the nuts—is crucial. Too little torque, and your wheels could come loose. Too much, and you risk damaging the wheel studs, rotors, or even the wheels themselves.

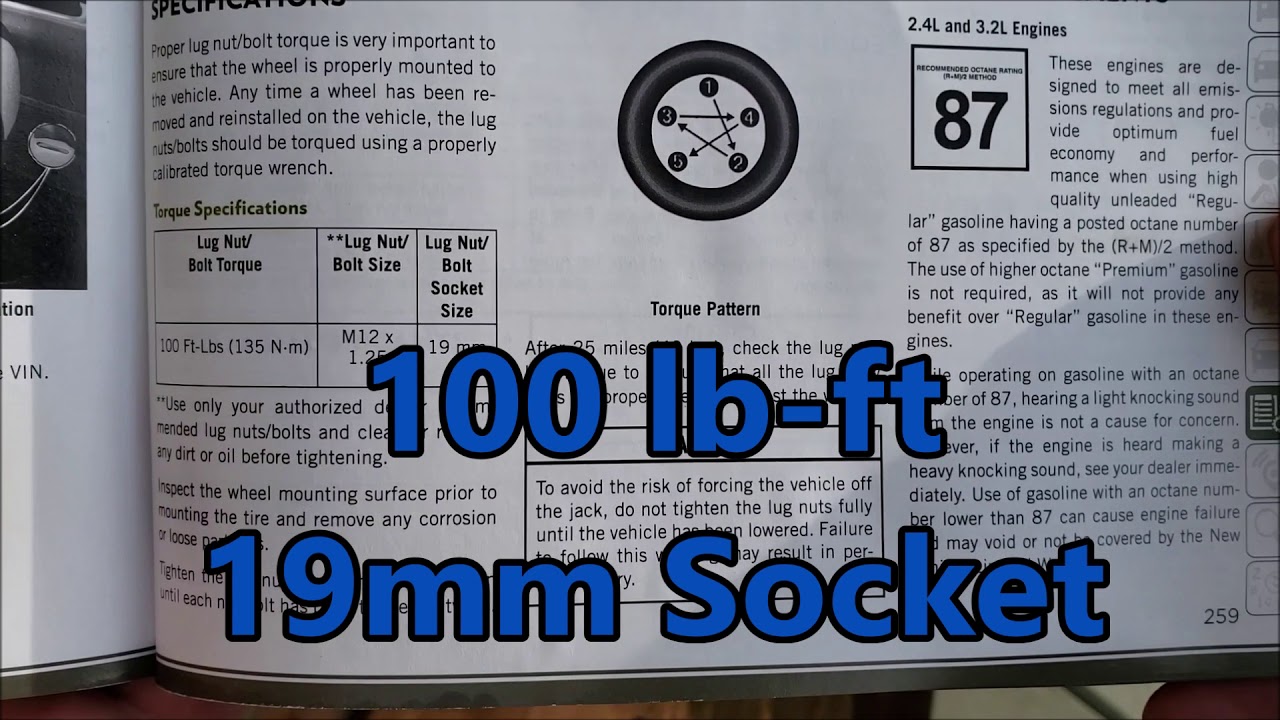

The recommended Jeep Wrangler lug nut torque specifications vary slightly depending on the model year and wheel type. Always consult your owner's manual for the precise figures for your specific Wrangler. This information is essential for maintaining the integrity of your vehicle and ensuring a safe driving experience.

Historically, lug nuts have been a crucial component of wheeled vehicles. As Jeeps evolved from their military origins to the popular off-road vehicle we know today, the importance of proper lug nut torque has remained constant. With the Wrangler's focus on off-road capability, ensuring correct lug nut torque is even more critical due to the added stresses and vibrations encountered on challenging terrain. Incorrect tightening can lead to a host of issues, from wheel damage and vibrations to complete wheel detachment, posing significant safety risks.

Torque is measured in foot-pounds (ft-lbs) or Newton-meters (Nm). A torque wrench, a specialized tool designed to measure and apply a specific amount of rotational force, is essential for achieving accurate lug nut torque. Using a regular wrench and simply "tightening it up" is not sufficient and can lead to improper torque, potentially causing damage or creating hazardous driving conditions.

One key benefit of correct Jeep Wrangler lug torque is improved safety. Securely fastened wheels minimize the risk of wheel separation, preventing accidents and keeping you and your passengers safe on and off the road.

Another advantage is the prevention of costly repairs. Over-torquing can damage wheel studs, rotors, and wheels, leading to expensive replacements. Proper torque prevents these issues, saving you money in the long run.

Finally, maintaining the correct lug nut torque contributes to a smoother, more comfortable ride. Properly torqued wheels reduce vibrations and ensure optimal wheel alignment, enhancing your driving experience.

Here's a step-by-step guide for torquing your Jeep Wrangler's lug nuts: 1. Consult your owner's manual for the correct torque specification. 2. Use a calibrated torque wrench. 3. Tighten the lug nuts in a star pattern to ensure even pressure distribution. 4. Re-torque the lug nuts after driving 50 miles, as they can settle.

Advantages and Disadvantages of Correct Lug Nut Torque

| Advantages | Disadvantages |

|---|---|

| Increased Safety | Requires specific tools (torque wrench) |

| Prevents costly repairs | Takes slightly more time than simply tightening |

| Smoother ride |

Best Practices: 1. Always use a calibrated torque wrench. 2. Follow the star pattern tightening sequence. 3. Re-torque after 50 miles. 4. Inspect lug nuts regularly for damage. 5. Consult your owner's manual for specific torque specifications.

FAQs: 1. What is the correct torque for my Wrangler? (Consult your owner's manual) 2. Can I use a regular wrench? (No, use a torque wrench) 3. How often should I check my lug nuts? (Regularly, especially after off-roading) 4. What is a star pattern? (A specific tightening sequence to ensure even pressure) 5. What are the signs of a loose lug nut? (Wobbling, vibrations) 6. Why is re-torquing important? (Lug nuts can settle after initial tightening) 7. Can I over-torque lug nuts? (Yes, and it can cause damage) 8. Where can I find a torque wrench? (Auto parts stores)

Tips and Tricks: Mark your torque wrench setting with tape for easy reference. Keep your torque wrench calibrated regularly for accurate readings.

In conclusion, understanding and applying the correct Jeep Wrangler lug nut torque is a fundamental aspect of responsible Wrangler ownership. While it might seem like a small detail, the proper torque plays a significant role in safety, preventing costly repairs, and ensuring a smooth, enjoyable ride. Investing in a quality torque wrench and following the recommended procedures will not only protect your investment but also enhance your peace of mind knowing that your wheels are securely attached. By taking the time to learn and implement these practices, you can confidently enjoy all the adventures your Wrangler has to offer, knowing that you've taken the necessary steps to stay safe on and off the road. Don't underestimate the importance of this seemingly small detail - it could make all the difference in your next off-road excursion.

Unveiling the enigma exploring the concept of forbidden knowledge

Electrifying duluth exploring minnesota powers impact

Unlocking wake countys 23 24 schedule