Trailer Wheel Bolt Pattern Guide: Ensuring a Safe and Secure Tow

Ever experienced that unsettling wobble while towing your trailer? It might be a sign of improperly matched wheel bolt patterns. This seemingly small detail plays a huge role in the safety and stability of your towing experience. Understanding trailer wheel bolt patterns, sometimes referred to as lug patterns or bolt circles, is paramount for any trailer owner.

A trailer wheel bolt pattern is the specific arrangement of bolts or studs on the wheel hub that secure the wheel to your trailer axle. This pattern is defined by the number of lugs and the diameter of the circle on which these lugs are located, often referred to as the Pitch Circle Diameter (PCD). Getting this pattern right is not just about making sure the wheel fits; it's about ensuring a strong, reliable connection capable of withstanding the stresses of towing.

While the precise origins of standardized trailer wheel bolt patterns are somewhat obscure, their importance emerged alongside the widespread adoption of trailers for various applications. As trailers became more common for hauling goods and recreational equipment, the need for interchangeable wheels and a standardized system for attachment became evident. This led to the development of common bolt patterns, allowing for easier maintenance and replacement of trailer wheels.

One of the most common issues related to trailer wheel bolt patterns is incorrect fitment. Using a wheel with an incompatible bolt pattern can lead to loose wheels, sheared lugs, and potentially catastrophic wheel detachment. This can damage your trailer, your vehicle, and put you and other drivers at risk. Ensuring you have the correct bolt pattern for your trailer axle is the first step towards safe towing.

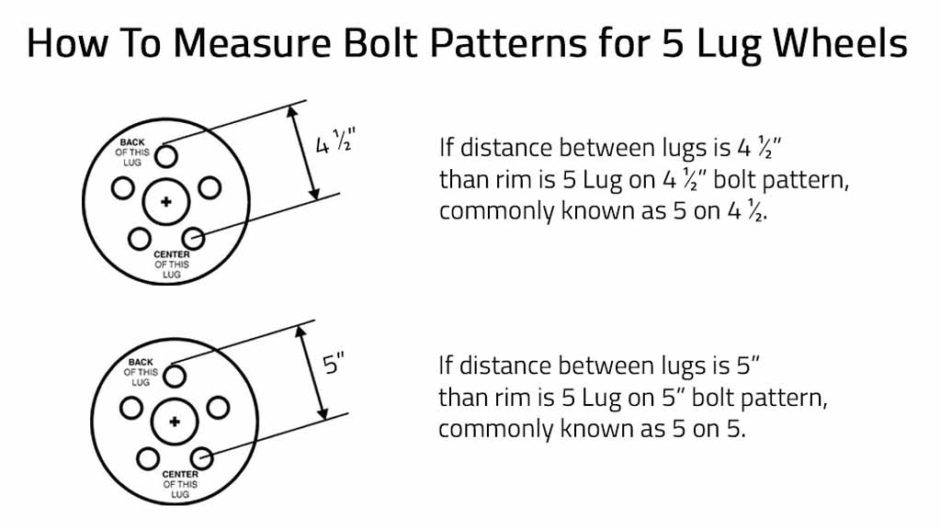

Identifying your trailer's wheel bolt pattern is crucial. It’s typically expressed as two numbers: the number of lugs and the PCD. For instance, a common pattern is 5 on 4.5 inches, indicating five lug nuts and a PCD of 4.5 inches. Accurately measuring the PCD involves precise measurements between lug centers. Various tools and techniques exist for this, and referencing your trailer's documentation or consulting a wheel specialist can ensure accurate identification.

Understanding your trailer's bolt configuration is essential for selecting the right replacement wheels or adapting different wheels. Several resources can aid in this process, including online wheel bolt pattern guides, vehicle specifications databases, and consulting with tire and wheel professionals.

One key benefit of adhering to the correct bolt pattern is enhanced safety. A properly secured wheel contributes to the overall stability of the trailer, minimizing the risk of accidents due to wheel detachment. Proper fitment also ensures even load distribution, reducing stress on the wheel bearings and extending their lifespan.

Another advantage is the ease of maintenance and repairs. Using standardized bolt patterns simplifies wheel replacement. Having a common bolt pattern makes finding replacements much easier, whether you're on the road or back home.

Finally, using the correct bolt pattern avoids costly damage. An incompatible bolt pattern can damage wheel studs, the hub, and even the trailer itself. The cost of repairs can far outweigh the investment of time and effort to determine the correct bolt pattern from the outset.

Advantages and Disadvantages of Different Trailer Wheel Bolt Patterns

| Bolt Pattern | Advantages | Disadvantages |

|---|---|---|

| 5 on 4.5" | Common, readily available parts | Can be overloaded on heavier trailers |

| 6 on 5.5" | Stronger, suitable for heavier loads | Less common, potentially harder to find replacements |

Frequently Asked Questions:

Q: How do I measure my trailer’s bolt pattern? A: Measure from the center of one lug nut to the center of the opposite lug nut for even-numbered lug patterns. For odd-numbered patterns, methods vary slightly, and consulting a guide or professional is recommended.

Q: Can I use a different bolt pattern? A: No, using a mismatched bolt pattern is unsafe and can lead to wheel detachment.

Q: What is PCD? A: PCD stands for Pitch Circle Diameter, the diameter of the circle on which the lug nuts are centered.

Q: Where can I find my trailer’s bolt pattern information? A: Check your trailer’s owner’s manual, the trailer’s VIN plate, or consult the manufacturer.

Q: What are common trailer wheel bolt patterns? A: Common patterns include 4 on 4, 5 on 4.5, 5 on 5, and 6 on 5.5.

Q: What happens if I use the wrong bolt pattern? A: Using an incorrect bolt pattern can cause the wheel to detach, leading to accidents and damage.

Q: Are all trailer wheel studs the same size? A: No, stud sizes can vary. Ensure compatibility with your wheel's lug nuts.

Q: What are the different types of lug nuts? A: There are various types, including acorn, conical, and lug bolts. The correct type depends on your wheel and hub design.

In conclusion, understanding and correctly implementing trailer wheel bolt patterns is fundamental to safe and reliable towing. From ensuring compatibility between your wheels and axle to understanding the importance of PCD and proper torque specifications, attention to these details can prevent accidents, minimize maintenance costs, and ensure a smooth, worry-free towing experience. Don't overlook this critical aspect of trailer maintenance; verify your bolt pattern and invest in properly fitted wheels for peace of mind on the road. By prioritizing safety and taking the time to understand your trailer's specific requirements, you contribute to your own safety and the safety of others on the road.

Navigating the big black lips meme phenomenon

Biomedical science bachelors at usm a glimpse into malaysias cutting edge program

Cheng leis marital status unraveling the mystery