Wheel Lug Measurement: A Deep Dive into Bolt Patterns

Ever stared at a wheel, bewildered by the seemingly cryptic arrangement of lugs? You're not alone. Knowing how to determine wheel lug measurements is essential for anyone who's ever changed a tire, upgraded their wheels, or just wants to understand the mechanics behind those spinning metal discs. It's a fundamental skill often overlooked, yet critical for safe driving. This guide unlocks the secrets of wheel lug sizing, providing you with the knowledge to confidently tackle wheel-related projects.

Correctly identifying your wheel lug dimensions is akin to knowing your blood type – crucial in emergencies and helpful for preventative care. A mismatched wheel can lead to vibrations, sheared lugs, and even wheel detachment – a recipe for disaster. Understanding your car's specific requirements ensures a perfect fit and safe operation. This seemingly small detail plays a monumental role in keeping your ride smooth and secure.

The history of wheel lug measurement is intertwined with the evolution of the automobile itself. As cars transitioned from horse-drawn carriages to motorized vehicles, standardized lug patterns emerged. Initially, variations were widespread, reflecting the diverse approaches of early automakers. Over time, standardization became paramount for interchangeability and ease of maintenance. Today, specific lug patterns are associated with vehicle makes and models, simplifying wheel selection and replacement.

A key issue surrounding wheel lug measurement is the potential for misidentification. Several measurement systems exist, adding to the complexity. Understanding the differences between these systems – whether metric or imperial – is paramount for accurate measurement. Misinterpreting these measurements can result in purchasing the wrong wheels, leading to safety hazards and wasted time and money. Therefore, precise measurement is not just about numbers; it's about safety and compatibility.

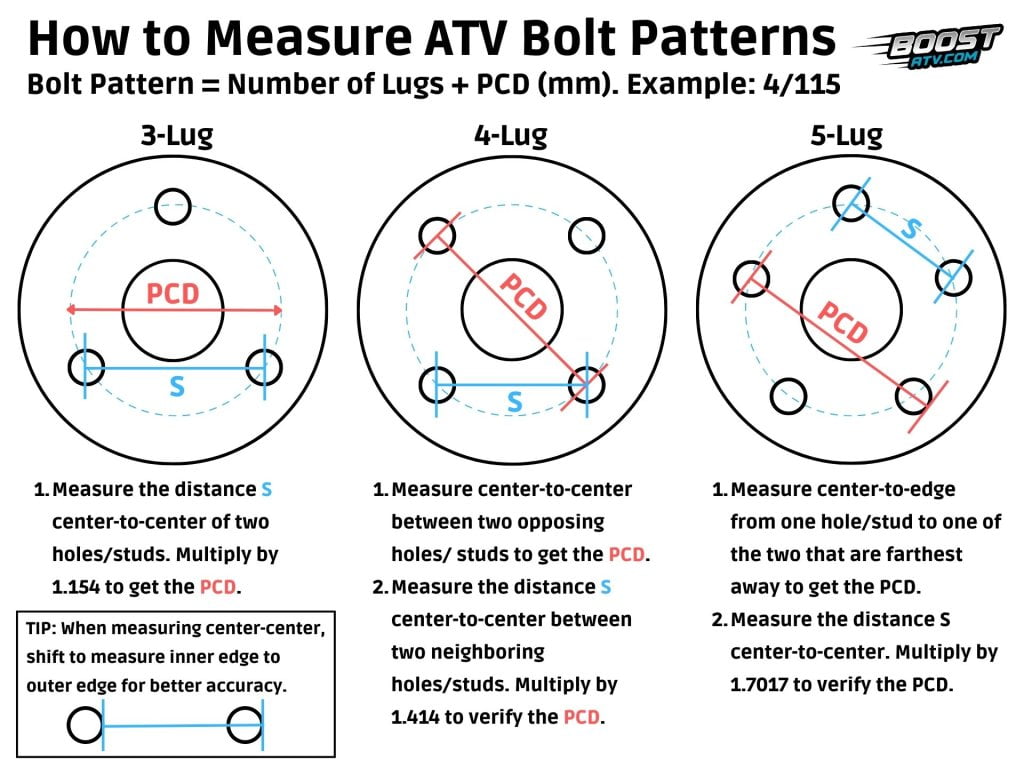

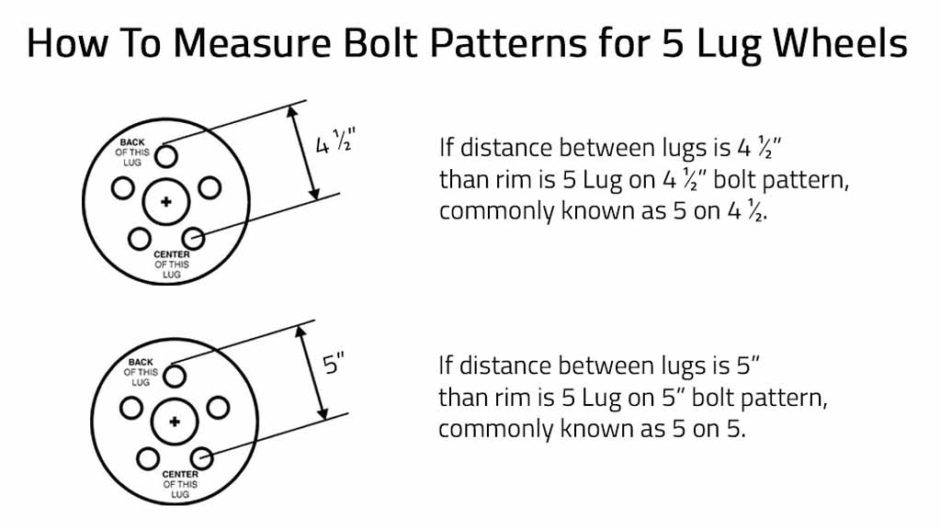

The primary measurements involved in sizing wheel lugs are the bolt pattern, the thread pitch, and the lug nut size. The bolt pattern refers to the number of lugs and the diameter of the circle formed by the lug holes. Thread pitch defines the distance between the threads on the lug stud. The lug nut size encompasses its diameter and thread type. Each of these measurements is crucial for proper wheel fitment.

Benefit 1: Ensuring Proper Wheel Fitment: Accurately measuring wheel lugs guarantees a perfect match between the wheel and the vehicle hub, preventing vibrations and ensuring a secure connection. For example, a wheel with a 5x114.3mm bolt pattern will not fit a vehicle with a 5x100mm bolt pattern.

Benefit 2: Enhancing Safety: Correct lug measurements contribute to overall vehicle safety. Loose or improperly fitted wheels can detach, leading to serious accidents. Accurately measured lugs provide a strong and stable connection, minimizing the risk of wheel detachment.

Benefit 3: Preventing Damage: Using the wrong lugs can damage the wheel hubs, studs, and the wheels themselves. Correct measurements protect these components from wear and tear, extending their lifespan and saving you on costly repairs.

Step-by-step guide for measuring wheel lugs:

1. For 4 or 6 lug patterns, measure from the center of one lug to the center of the lug directly opposite. 2. For 5-lug patterns, measure from the back of one lug hole to the center of the opposite lug hole.

Advantages and Disadvantages of Measuring Wheel Lugs

| Advantages | Disadvantages |

|---|---|

| Ensures safety | Can be time-consuming if unfamiliar with the process |

| Prevents costly repairs | Requires specific tools |

| Easy process once learned | Potential for mismeasurement if not careful |

FAQ:

1. What tools do I need? A ruler or caliper.

2. What if I can't find my bolt pattern? Consult your vehicle's owner's manual.

3. Are all lug nuts the same size? No, they vary in diameter and thread type.

4. What is the difference between metric and imperial measurements? Metric uses millimeters, while imperial uses inches.

5. Can I use aftermarket lugs? Yes, but ensure they match your vehicle's specifications.

6. What if my wheel vibrates after installation? Check your lug nut torque and ensure the wheels are properly balanced.

7. How often should I check my lug nuts? Periodically, especially after rotating or changing tires.

8. Can I measure lug nuts without removing the wheel? Yes, but it might be more challenging.

Tips and Tricks

Clean the lug holes before measuring to ensure accurate readings. Use a digital caliper for greater precision.

Knowing how to measure wheel lugs empowers you to make informed decisions about your vehicle's wheels and tires. It's a skill that not only ensures a smooth and safe ride but also prevents costly repairs and potential hazards. By understanding the importance of bolt patterns, thread pitch, and lug nut sizes, you become an active participant in maintaining your vehicle's well-being. This knowledge translates to enhanced safety, improved performance, and the peace of mind that comes with knowing your wheels are securely attached. Take the time to learn this crucial skill – it's an investment in your safety and the longevity of your vehicle. Don't hesitate to consult resources like your owner's manual or a trusted mechanic for further guidance. Your wheels are quite literally what keep you rolling – ensure they're properly fitted and secured by mastering the art of wheel lug measurement.

Unlocking fedex field club level your ultimate guide

Refreshing your home with clary sage sw 6178 exterior paint

Transform your bathroom with benjamin moore paint