Wiring the Future: Revolutionizing Automotive Electrical Systems with Auto Wire Harness Kits

The automotive industry is in a state of constant evolution, driven by relentless innovation and the pursuit of enhanced performance, safety, and efficiency. Underpinning this transformation is a complex network of electrical systems, intricately woven together by the often-overlooked yet critical component: the auto wire harness kit. These pre-assembled bundles of wires, connectors, and terminals are the nervous system of modern vehicles, enabling everything from powering the engine to controlling sophisticated infotainment systems.

Imagine a car without a structured electrical system – a chaotic jumble of wires snaking their way through the vehicle, prone to shorts, malfunctions, and potential fires. This is the scenario that automotive wire harness kits prevent. They provide a standardized, organized, and protected pathway for electrical currents to flow, ensuring reliable operation and reducing the risk of electrical hazards.

The history of automotive wiring harnesses parallels the development of the automobile itself. Early vehicles relied on simple wiring setups, but as vehicles became more complex, so too did their electrical systems. The introduction of features like electric starters, lighting, and eventually, advanced electronics, necessitated the development of more sophisticated wiring solutions. Auto wire harness kits emerged as a way to manage this increasing complexity, allowing manufacturers to streamline the production process and ensure consistent quality.

The significance of automotive wiring harness kits cannot be overstated. They are fundamental to the functioning of every modern vehicle, from everyday passenger cars to high-performance race cars. These kits not only ensure the reliable operation of essential systems but also play a crucial role in safety features such as airbags, anti-lock brakes, and electronic stability control. Moreover, they enable the integration of cutting-edge technologies like autonomous driving systems and advanced driver-assistance systems (ADAS).

However, the increasing complexity of vehicle electrical systems also presents challenges for auto wire harness kit design and manufacturing. The demand for smaller, lighter, and more durable harnesses that can accommodate high data transfer rates and withstand harsh environmental conditions is pushing the boundaries of materials science and manufacturing techniques. Addressing these challenges is critical to ensuring the continued advancement of automotive technology.

An auto wire harness kit is essentially a pre-assembled collection of wires, terminals, connectors, and protective coverings designed to transmit electrical signals and power throughout a vehicle. A simplified example would be a harness for a car's headlights, which includes wires to connect the battery to the headlight switch and then to the headlights themselves, along with connectors to ensure secure connections and insulation to protect the wires.

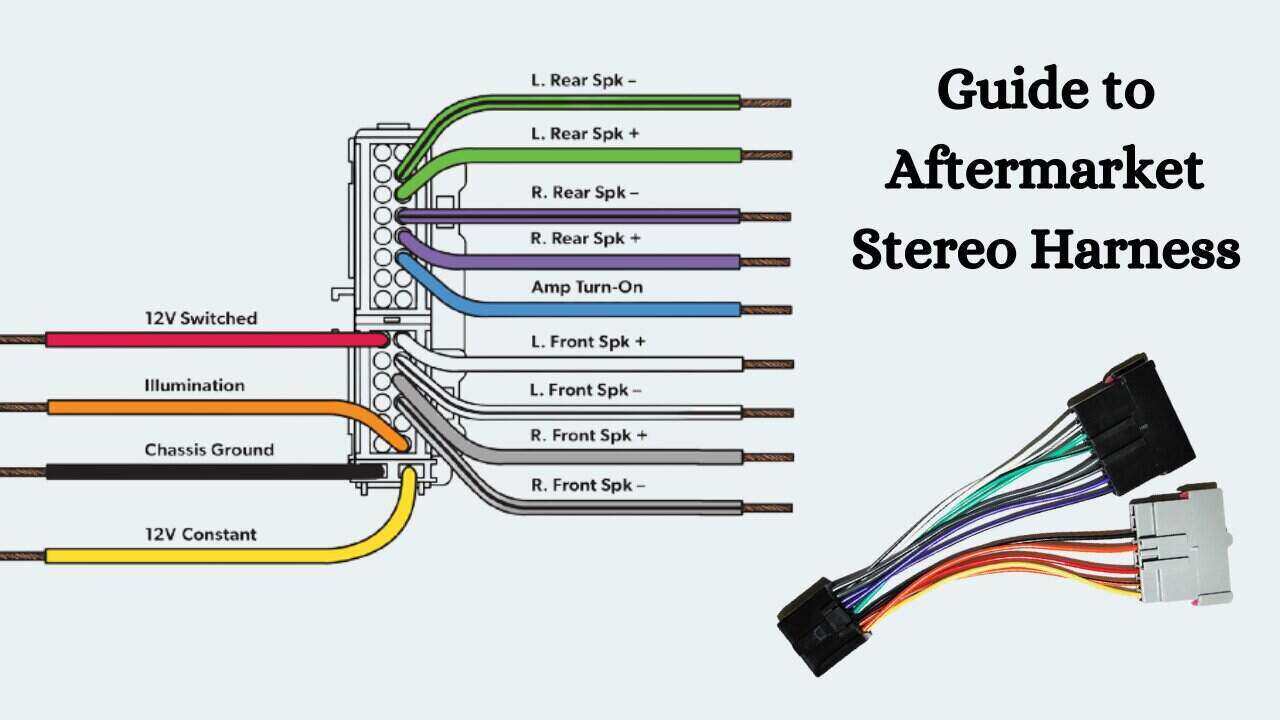

Benefits of using pre-assembled auto wiring harness kits include: streamlined installation, reduced labor costs, and enhanced reliability. For instance, using a kit for an aftermarket stereo installation eliminates the need to cut and splice wires individually, saving time and ensuring a professional-looking result.

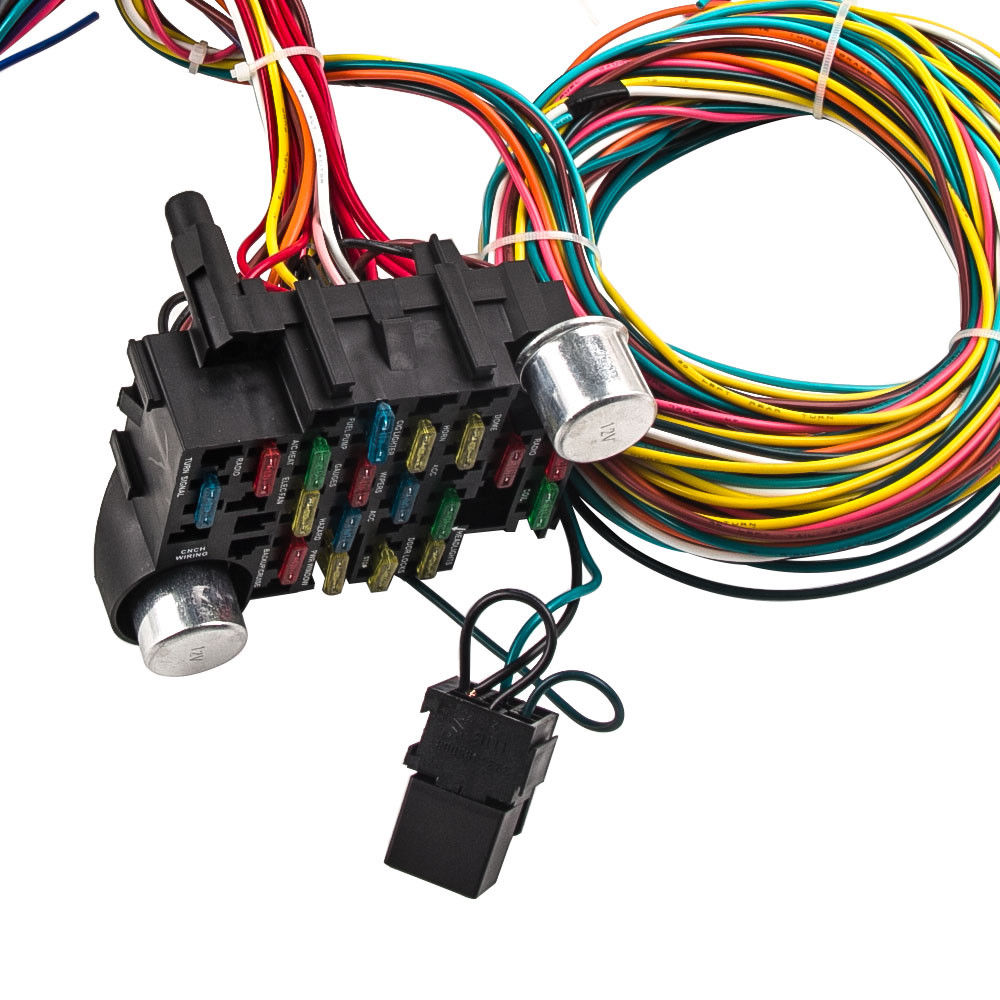

Creating a custom auto wire harness involves meticulous planning, including identifying the required circuits, selecting appropriate wire gauges, and designing the harness layout. Successful examples include custom harnesses for classic car restorations and modified vehicles with specialized electrical systems.

Advantages of custom-made harnesses include precise fit and functionality tailored to the specific application. However, disadvantages can include higher costs compared to off-the-shelf kits.

Advantages and Disadvantages of Auto Wire Harness Kits

| Advantages | Disadvantages |

|---|---|

| Simplified Installation | Can be costly for specialized applications |

| Reduced Labor Costs | May require modification for unique installations |

| Enhanced Reliability | Difficult to repair internal damage |

Best practices for working with auto wire harnesses include using proper crimping tools for secure connections, carefully routing the harness to avoid interference and damage, and using protective coverings to prevent abrasion and environmental exposure.

Common challenges include diagnosing wiring faults and repairing damaged harnesses. Specialized tools and knowledge are often required for effective troubleshooting and repair.

Frequently Asked Questions about Auto Wire Harness Kits:

1. What is an auto wire harness kit? (Answered above)

2. Why are auto wire harnesses important? (Answered above)

3. How do I choose the right auto wire harness kit? It depends on the specific application and vehicle. Research and consulting with experts is recommended.

4. Can I install an auto wire harness kit myself? It depends on the complexity of the kit and your experience level.

5. Where can I buy auto wire harness kits? They are available from automotive parts suppliers, online retailers, and specialty shops.

6. How do I troubleshoot problems with an auto wire harness? Consult a wiring diagram and use diagnostic tools like a multimeter.

7. What are the different types of auto wire harnesses? There are various types, including engine harnesses, body harnesses, and chassis harnesses.

8. How can I maintain my auto wire harness? Regular inspection and cleaning can help prevent problems.

Tips and tricks for working with auto wire harnesses include labeling wires for easy identification, using heat shrink tubing to protect connections, and securing the harness with zip ties or other appropriate fasteners.

In conclusion, auto wire harness kits are integral components of modern vehicles, playing a crucial role in ensuring reliable operation, safety, and the integration of advanced technologies. From simplifying installation and reducing labor costs to enabling complex electrical systems and enhancing safety features, the benefits of using these pre-assembled systems are undeniable. While challenges exist in designing and manufacturing harnesses that meet the ever-increasing demands of the automotive industry, ongoing innovation in materials and manufacturing techniques promises to pave the way for even more sophisticated and efficient auto wire harness kits in the future. Understanding the importance, function, and proper implementation of these critical components is essential for anyone involved in the automotive industry, from mechanics and technicians to engineers and designers. Investing in high-quality auto wire harness kits and adhering to best practices for installation and maintenance are key to ensuring the optimal performance, reliability, and longevity of your vehicle’s electrical systems. Embrace the future of automotive wiring and explore the possibilities that auto wire harness kits offer.

Decoding the mystique of paint color matching apps

Behr oil based wood stain a deep dive

Sw wall street paint a sophisticated choice